"Chariotoflove" (chariotoflove)

"Chariotoflove" (chariotoflove)

10/05/2020 at 22:29 ē Filed to: repairlopnik

0

0

100

100

"Chariotoflove" (chariotoflove)

"Chariotoflove" (chariotoflove)

10/05/2020 at 22:29 ē Filed to: repairlopnik |  0 0

|  100 100 |

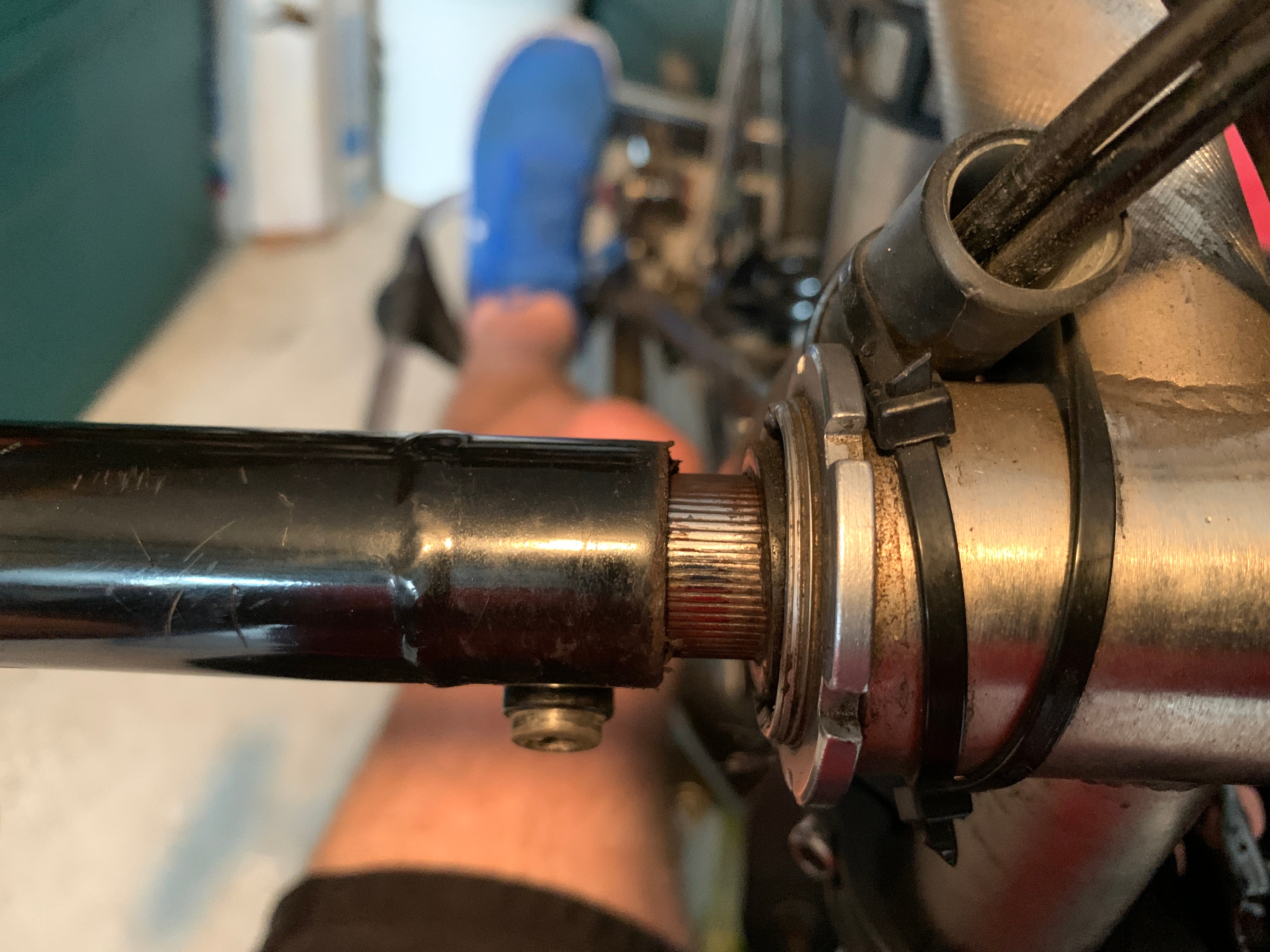

...professional, hobbyist, and aspiring. I am having difficulty with the handlebars on my hand cycle. The handlebar is held on each side to the spindle by clamping with a screw, as you see here.

Well, it keeps slipping. This results in the spider sliding out on the other side, which takes the chainrings out of line with the derailleur, and then I canít shift properly. Plus, the bearing cassettes start to slide out too. But Iíve already tightened it as much as it will go. Here it is when you slide the handlebar off more.

My idea is to put a shim of some sort in there, a sleeve that will increase the diameter of the spindle and then tighten the handlebar screw over that. My questions to you are thus:

Is this a good solution?

What material would you suggest I use if it is a good solution?

If it is not a good solution, what is an alternate one?

Thanks gang!

UPDATE: more pics.

I donít think the splines were ever meant to fit grooves for grip. Perhaps to prevent seizing? You can see the clamping collar is bent from being tightened as much as it can be.

This is what we'll show whenever you publish anything on Kinja:

> Chariotoflove

This is what we'll show whenever you publish anything on Kinja:

> Chariotoflove

10/05/2020 at 20:53 |

|

Beer can.

Source: Zen and the Art of Motorcycle Maintenance

ď I thought I would wait until something went wrong with his machine and then I would help him fix it and that way get him into it, but I goofed that one myself because I didnít understand this difference in the way he looked at things.

His handlebars had started slipping. Not badly, he said, just a little when you shoved hard on them. I warned him not to use his adjustable wrench on the tightening nuts. It was likely to damage the chrome and start small rust spots. He agreed to use my metric sockets and box-ends. When he brought his motorcycle over I got my wrenches out but then noticed that no amount of tightening would stop the slippage, because the ends of the collars were pinched shut.

ďYouíre going to have to shim those out,Ē I said.

ďWhatís shim?Ē

ďItís a thin, flat strip of metal. You just slip it around the handlebar under the collar there and it will open up the collar to where you can tighten it again. You use shims like that to make adjustments in all kinds of machines.Ē

ďOh,Ē he said. He was getting interested. ďGood. Where do you buy them?Ē

ďIíve got some right here,Ē I said gleefully, holding up a can of beer in my hand.

He didnít understand for a moment. Then he said, ďWhat, the can?Ē

ďSure,Ē I said, ďbest shim stock in the world.Ē

I thought this was pretty clever myself. Save him a trip to God knows where to get shim stock. Save him time. Save him money.

But to my surprise he didnít see the cleverness of this at all. In fact he got noticeably haughty about the whole thing. Pretty soon he was dodging and filling with all kinds of excuses and, before I realized what his real attitude was, we had decided not to fix the handlebars after all.

As far as I know those handlebars are still loose. And I believe now that he was actually offended at the time. I had had the nerve to propose repair of his new eighteen-hundred dollar BMW, the pride of a half-century of German mechanical finesse, with a piece of old beer can!

Ach, du lieber!

Since then we have had very few conversations about motorcycle maintenance. None, now that I think of it. You push it any further and suddenly you are angry, without knowing why.

I should say, to explain this, that beer-can aluminum is soft and sticky, as metals go. Perfect for the application. Aluminum doesnít oxidize in wet weather...or, more precisely, it always has a thin layer of oxide that prevents any further oxidation. Also perfect.

In other words, any true German mechanic, with a half-century of mechanical finesse behind him, would have concluded that this particular solution to this particular technical problem was perfect.

For a while I thought what I should have done was sneak over to the workbench, cut a shim from the beer can, remove the printing and then come back and tell him we were in luck, it was the last one I had, specially imported from Germany. That would have done it. A special shim from the private stock of Baron Alfred Krupp, who had to sell it at a great sacrifice. Then he would have gone gaga over it.

That Kruppís-private-shim fantasy gratified me for a while, but then it wore off and I saw it was just being vindictive. In its place grew that old feeling Iíve talked about before, a feeling that thereís something bigger involved than is apparent on the surface. You follow these little discrepancies long enough and they sometimes open up into huge revelations. There was just a feeling on my part that this was something a little bigger than I wanted to take on without thinking about it, and I turned instead to my usual habit of trying to extract causes and effects to see what was involved that could possibly lead to such an impasse between Johnís view of that lovely shim and my own. This comes up all the time in mechanical work. A hang-up. You just sit and stare and think, and search randomly for new information, and go away and come back again, and after a while the unseen factors start to emerge.

What emerged in vague form at first and then in sharper outline was the explanation that I had been seeing that shim in a kind of intellectual, rational, cerebral way in which the scientific properties of the metal were all that counted. John was going at it immediately and intuitively, grooving on it. I was going at it in terms of underlying form. He was going at it in terms of immediate appearance. I was seeing what the shim meant. He was seeing what the shim was. Thatís how I arrived at that distinction. And when you see what the shim is,in this case, itís depressing. Who likes to think of a beautiful precision machine fixed with an old hunk of

junk?

I guess I forgot to mention John is a musician, a drummer, who works with groups all over town and makes a pretty fair income from it. I suppose he just thinks about everything the way he thinks about drumming...which is to say he doesnít really think about it at all. He just does it. Is with it. He just responded to fixing his motorcycle with a beer can the way he would respond to someone dragging the beat while he was playing. It just did a big thud with him and that was it. He didnít want any part of it.

At first this difference seemed fairly minor, but then it grewóand grewóand grewóuntil I began to see why I missed it. Some things you miss because theyíre so tiny you overlook them. But some things you donít see because theyíre so huge. We were both looking at the same thing, seeing the same thing, talking about the same thing, thinking about the same thing, except he was looking, seeing, talking and thinking from a completely different dimension.

He really does care about technology. Itís just that in this other dimension he gets all screwed up and is rebuffed by it. It just wonít swing for him. He tries to swing it without any rational premeditation and botches it and botches it and botches it and after so many botches gives up and just kind of puts a blanket curse on that whole nuts-and-bolts scene. He will not or cannot believe there is anything in this world for which grooving is not the way to go.

Thatís the dimension heís in. The groovy dimension. Iím being awfully square talking about all this mechanical stuff all the time. Itís all just parts and relationships and analyses and syntheses and figuring things out and it isnít really here. Itís somewhere else, which thinks itís here, butís a million miles away. This is what itís all about. Heís on this dimensional difference which underlay much of the cultural changes of the sixties, I think, and is still in the process of reshaping our whole national outlook on things. The ďgeneration gapĒ has been a result of it. The names ďbeatĒ and ďhipĒ grew out of it. Now itís become apparent that this dimension isnít a fad thatís going to go away next year or the year after. Itís here to stay because itís a very serious and important way of looking at things that looks incompatible with reason and order and responsibility but actually is not. Now we are down to the root of things.Ē

RooseveltDad

> Chariotoflove

RooseveltDad

> Chariotoflove

10/05/2020 at 20:54 |

|

The shaft that is more exposed in the second picture looks pretty worn to me, like it used to have bumps / ridges / surface area to ďbiteĒ into the inside surface of the handlebars, and itís worn down now. Is replacing that piece an option? Or am I misreading the situation?

I like cars: Jim Spanfeller is one ugly motherfucker

> Chariotoflove

I like cars: Jim Spanfeller is one ugly motherfucker

> Chariotoflove

10/05/2020 at 20:55 |

|

In that last pic, is it splined under the handlebar? This is sketchy but would probably work:

https://www.thesamba.com/vw/forum/archive/index.php/o-tót-718018ó.html

Highlander-Datsuns are Forever

> Chariotoflove

Highlander-Datsuns are Forever

> Chariotoflove

10/05/2020 at 20:58 |

|

The splines look flat and crushed. At least Iíd say you need a new spindle, perhaps even new handle bar cranks. IIRC these are a steer-crank combo so they are very specific and will probably have to come from the manufacture or just upgrade to campy.

Highlander-Datsuns are Forever

> Highlander-Datsuns are Forever

Highlander-Datsuns are Forever

> Highlander-Datsuns are Forever

10/05/2020 at 21:02 |

|

Also the spindle shouldnít move side to side, it looks like a traditional cup and cone bearing just like an old school bottom bracket. Is it possible the bearings are shot too?

Exage03040 @ opposite-lock.com

> RooseveltDad

Exage03040 @ opposite-lock.com

> RooseveltDad

10/05/2020 at 21:03 |

|

Yeah, if Iím honest, the spl ines look worn down . This would be why itís slipping with the set screw completely tightened.

Beefchips

> Chariotoflove

Beefchips

> Chariotoflove

10/05/2020 at 21:03 |

|

Y ou could use a dremel to cut the notch in the spindle a little wider. Then the screw could clamp down a little further. But yeah, as RooseveltDad mentioned, those look like some very worn splines...

Bandit

> Chariotoflove

Bandit

> Chariotoflove

10/05/2020 at 21:04 |

|

Temporarily a beer can shim should work well. Any particular reason itís splined? Their attachment strategy doesnít make too much sense if they wanted to take advantage of the splines for transferring force.†

Chariotoflove

> This is what we'll show whenever you publish anything on Kinja:

Chariotoflove

> This is what we'll show whenever you publish anything on Kinja:

10/05/2020 at 21:04 |

|

This is the content that keeps me renewing my platinum membership. Thanks!

Chariotoflove

> RooseveltDad

Chariotoflove

> RooseveltDad

10/05/2020 at 21:05 |

|

Yes, it is and they are. I just donít have many solutions that donít involve replacing the thing.

Chariotoflove

> Exage03040 @ opposite-lock.com

Chariotoflove

> Exage03040 @ opposite-lock.com

10/05/2020 at 21:06 |

|

I think youíre correct.

Chariotoflove

> Highlander-Datsuns are Forever

Chariotoflove

> Highlander-Datsuns are Forever

10/05/2020 at 21:08 |

|

Yeah, they are crushed. I donít have a lot of money right now, or I would upgrade to a new crankset. I can get a new spindle from the builder, but he doesnít build it this way with custom handlebars and crank† and all anymore. Heís moved to Shimano cranksets. Iíll do what I have to, but Iím wondering if I have a chance of increasing the grab to make this work with friction.

Chariotoflove

> Highlander-Datsuns are Forever

Chariotoflove

> Highlander-Datsuns are Forever

10/05/2020 at 21:09 |

|

The spindle doesnít move, but the cassette will slip out of itís resting place given the extra room. I donít think the bearings are bad. It turns smoothly.

Highlander-Datsuns are Forever

> Chariotoflove

Highlander-Datsuns are Forever

> Chariotoflove

10/05/2020 at 21:10 |

|

Clean it really well, JB Weld.

I donít think a shim will hold, the force will just work it loose.

Chariotoflove

> I like cars: Jim Spanfeller is one ugly motherfucker

Chariotoflove

> I like cars: Jim Spanfeller is one ugly motherfucker

10/05/2020 at 21:12 |

|

Yes, but itís not supported entirely by the splines so that it doesnít slip† when you turn, only moves laterally, because there is a pin and notch you donít see. Which is by way of saying this idea might work.

jminer

> Chariotoflove

jminer

> Chariotoflove

10/05/2020 at 21:15 |

|

I wasnít going to quote Zen and the art of Motorcycle Maintenance, but I was going to recommend you use a beer/soda can as a shim.† Should add just enough diameter to let it bite and hopefully work better.

MrDakka

> Chariotoflove

MrDakka

> Chariotoflove

10/05/2020 at 21:18 |

|

Can you drill through both and put in a bolt or pin through it?

Nom De Plume

> Chariotoflove

Nom De Plume

> Chariotoflove

10/05/2020 at 21:22 |

|

C onfused by the photos a bit where I doubt I would be in person.

I see two problems offhand. First is you appear to have fatigued the metal clamp. You can see there is no longer a gap that would allow maintaining tension. Once this bottoms out tightening more is not going to help.

Second is probable need to get both surfaces very clean and free of any jagged metal remaining. Clean, not polished. No contaminants means less to slide on or lubricate said sliding.

With this accomplished you could try something like loctite green which would normally cure strong enough to require a heat gun to break loose. I have doubts the bond will be that permanent here. Iíd take a very measured approach to how much I use. This isnít the blue stuff you just coat the entire circumference of threads with.

Green loctite is an industrial product youíll need to buy online or look for a local supplier who sells small quantities.††

farscythe - makin da cawfee!

> Chariotoflove

farscythe - makin da cawfee!

> Chariotoflove

10/05/2020 at 21:25 |

|

welp..i was going to suggest glueing the fucker down

but...have you considered capping it?

i realize the handles might not be feasible...but the basic idea is the same....grips cant run away if they are blocked

PowderHound

> This is what we'll show whenever you publish anything on Kinja:

PowderHound

> This is what we'll show whenever you publish anything on Kinja:

10/05/2020 at 21:31 |

|

I use a rainier shim in the seatpost for my commuter. Hasnít slipped in years

gettingoldercarguy

> This is what we'll show whenever you publish anything on Kinja:

gettingoldercarguy

> This is what we'll show whenever you publish anything on Kinja:

10/05/2020 at 21:33 |

|

I knew the book early.† Good reference.

gettingoldercarguy

> Chariotoflove

gettingoldercarguy

> Chariotoflove

10/05/2020 at 21:37 |

|

Do you have a source diagram/drawing of what youíre looking at?

This'd be fun to model a solution to I think.

Chariotoflove

> Beefchips

Chariotoflove

> Beefchips

10/05/2020 at 21:38 |

|

Yeah, they are.†

Chariotoflove

> Highlander-Datsuns are Forever

Chariotoflove

> Highlander-Datsuns are Forever

10/05/2020 at 21:39 |

|

Maybe both?

Chariotoflove

> jminer

Chariotoflove

> jminer

10/05/2020 at 21:39 |

|

Yeah, it might. Cheap enough to try.

Chariotoflove

> MrDakka

Chariotoflove

> MrDakka

10/05/2020 at 21:40 |

|

You know, that might do it!

Chariotoflove

> Nom De Plume

Chariotoflove

> Nom De Plume

10/05/2020 at 21:41 |

|

I have tried cleaning and using loctite red, but it didnít hold for long. I think your assessment of the clamp is correct. Thatís why I was thinking the solution I was.†

ClassicDatsunDebate

> Chariotoflove

ClassicDatsunDebate

> Chariotoflove

10/05/2020 at 21:42 |

|

If the splines are very flat and warn, the shim method might still slip. I still see a gap in the split area so you could put some neversieze on the bolt and carefully tighten it as much as you dare.

If you have the time and patience, you can use a triangle file to Ďsharpení the flattened splines by beveling them. Run the pointy part of the triangle in the existing grooves to create a sharper edge that may have a better chance to bite into the slip collar as you tighten it.

You can also try loctite red on the splines. Thereís a chance that might hold depending on how much axial force happens when you crank.

Chariotoflove

> farscythe - makin da cawfee!

Chariotoflove

> farscythe - makin da cawfee!

10/05/2020 at 21:43 |

|

Thatís a good solution that I have used before on my chair. What you canít see is that there is nowhere to put a cap on the outside, because I didnít photograph it.

Chariotoflove

> gettingoldercarguy

Chariotoflove

> gettingoldercarguy

10/05/2020 at 21:44 |

|

Not on hand, but I can go take some more photos after disassembling it.

Chariotoflove

> ClassicDatsunDebate

Chariotoflove

> ClassicDatsunDebate

10/05/2020 at 21:45 |

|

Good ideas. I could try the grooving with a dremel. I did try loctite red. It held for a while.

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/05/2020 at 21:48 |

|

†What about drilling a hole clean through the whole thing and putting a bolt or a quick release pin through it? Then tighten the sleeve as you normally would.

Rusty Vandura - www.tinyurl.com/keepoppo

> MrDakka

Rusty Vandura - www.tinyurl.com/keepoppo

> MrDakka

10/05/2020 at 21:49 |

|

†I suggested the same, but you beat me to it!

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/05/2020 at 21:50 |

|

Just Make sure you use something grade 5 or grade 8 and not the plain steel zinc coated pot metal rubbish that you get at the hardware store.

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/05/2020 at 21:51 |

|

†I've experimented with JB weld quite a lot and it has disappointed me every time. I would not count on that for something genuinely mechanical.

ClassicDatsunDebate

> Chariotoflove

ClassicDatsunDebate

> Chariotoflove

10/05/2020 at 21:53 |

|

I would use a triangle file over a dremmel. †Youíre just trying to rebuild the sharp shoulder on each spline. †Good luck!

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/05/2020 at 21:54 |

|

†I don't think you would need to wrap it all the way around, either, if you wanted to try that. You could try a piece that maybe goes a quarter of the way around and see if that gives you enough extra purchase. But I really think the pin or bolt going through in combination with tightening the clamp would do the trick. There are all manner of quick release pins and roll pins and other things available Amazon, eBay, bolt Depot.com.

Highlander-Datsuns are Forever

> Chariotoflove

Highlander-Datsuns are Forever

> Chariotoflove

10/05/2020 at 21:56 |

|

Sure why not.

gettingoldercarguy

> Chariotoflove

gettingoldercarguy

> Chariotoflove

10/05/2020 at 22:00 |

|

Looking for something I can put into solidworks

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

10/05/2020 at 22:01 |

|

Yeah, MrDakka suggested that too, and I think it might do it.

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

10/05/2020 at 22:02 |

|

I have a good hardware store I trust to help me find just the thing.

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

10/05/2020 at 22:02 |

|

Good to know. Iíve never used it.

Chariotoflove

> gettingoldercarguy

Chariotoflove

> gettingoldercarguy

10/05/2020 at 22:04 |

|

Iím not familiar with that package or its requirements.

Poor_Sh

> Chariotoflove

Poor_Sh

> Chariotoflove

10/05/2020 at 22:12 |

|

One thing I'd be worried about with the drilling thru method is that the splined cylinder is a hollow thin-walled tube. A big enough drill bit and the pressure required to puncture the tube could deform the tube first so that the hole is more like a tear, or that the strength is compromised. Start with a small bit and increase it a few times until you have the hole diameter you want.†

benjrblant

> Chariotoflove

benjrblant

> Chariotoflove

10/05/2020 at 22:29 |

|

didnít realize oppo had so many engineers on staff.

Chariotoflove

> Poor_Sh

Chariotoflove

> Poor_Sh

10/05/2020 at 22:31 |

|

Very good point. †See the updated pics I just added for the thickness of the tube.

Chariotoflove

> benjrblant

Chariotoflove

> benjrblant

10/05/2020 at 22:32 |

|

Theyíre like mice; for every one you see, there are a hundred you donít.

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/05/2020 at 22:33 |

|

I've had some significant disappointments with the stuff. It gives up it's adhesion and water breaks it down.

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

10/05/2020 at 22:35 |

|

That would be a problem. †Water gets in there a lot.

notsomethingstructural

> Chariotoflove

notsomethingstructural

> Chariotoflove

10/05/2020 at 22:40 |

|

I would try plumbing thread tape or cutting a strip of† packing gasket (maybe not all the way around if it wonít fit) before some of these more exotic solutions.†

Jb boin

> Chariotoflove

Jb boin

> Chariotoflove

10/05/2020 at 22:42 |

|

A ghetto solution could be to put hose clamps around the original integrated clamp.

Or to drill a hole that you would then thre ad at 180į of the slit then put a screw there .

Chariotoflove

> notsomethingstructural

Chariotoflove

> notsomethingstructural

10/05/2020 at 22:43 |

|

I was wondering i f gasket material would be tough enough to hold in this case or be too soft and allow sliding. But itís worth trying. I donít thread tape would be thick enough though.

Chariotoflove

> Jb boin

Chariotoflove

> Jb boin

10/05/2020 at 22:45 |

|

You know, I thought of the hose clamp, but I wonder if it is too light weight to apply the force for a tube this thick. A couple of others suggested the drill and bolt, and Iím warming to that idea.

notsomethingstructural

> Chariotoflove

notsomethingstructural

> Chariotoflove

10/05/2020 at 22:47 |

|

The thing about thread tape is if itís too thin just use more of it. Wrap that SOB 200 times and if it doesnít work just cut it off . Iím iffy on the packing gasket but itís so cheap itís worth a shot. The one thing thatís worth considering is it might push the splines on the opposite side of the gasket into engagement. Might work, might not, but for $5 Iíd try it first.

notsomethingstructural

> Chariotoflove

notsomethingstructural

> Chariotoflove

10/05/2020 at 22:48 |

|

Also, packing gasket is EXTREMELY grippy.†

Poor_Sh

> Chariotoflove

Poor_Sh

> Chariotoflove

10/05/2020 at 22:50 |

|

Oh yup. Iím back to team shim, but something I use a lot for cylindrical clamping slide resistance is low durometer thin rubber. Just wrap a thin rubber sheet around the splined tube then maybe pry the clamp open a tad to reset the force needed to compress it. It works for underwater stuff anyway lol I'm an ocean engineer.†

SilentButNotReallyDeadly...killed by G/O Media

> Chariotoflove

SilentButNotReallyDeadly...killed by G/O Media

> Chariotoflove

10/05/2020 at 22:50 |

|

The grooves were indeed to prevent seizing. The keyway (I assume) is to transfer your arm strength into the drive. And the bar clamp is what is supposed to keep it all together (whilst also looking like a cheap and not that well made solution for such an expensive and heavily used piece of kit). So, three options: first is to source a new handlebar since the one you have is fatigued; Second, create a shim for the driveshaft from an aluminium can or similar; Third, use carbon assembly paste from a bike shop on the shaft - the paste includes an inert Ď sandí that may help the bar grip the shaft while the base of the paste works as an antiseize.

Jb boin

> Chariotoflove

Jb boin

> Chariotoflove

10/05/2020 at 22:52 |

|

Depending on how itís made yo can make the slit a but longer and put a clamp here.

There are some heavier clamps than the usual worm screw type, like the ones used for exhausts.

Or something like that :

You could also cut the original ďearsĒ and put such a clamp (or multiples) that would clamp †all around and not just tightening on one side and also possibly on a larger surface.

PowderHound

> Chariotoflove

PowderHound

> Chariotoflove

10/05/2020 at 22:52 |

|

If there is enough room maybe some thread seal tape?

SilentButNotReallyDeadly...killed by G/O Media

> benjrblant

SilentButNotReallyDeadly...killed by G/O Media

> benjrblant

10/05/2020 at 22:53 |

|

I got my qualifications from the School of Armchair Opinions at Mostly Mistaken University. It took me decades and cost thousands but it was worth it for all those likes.

OPPOsaurus WRX

> Chariotoflove

OPPOsaurus WRX

> Chariotoflove

10/05/2020 at 22:57 |

|

I needed some parts for my bike so I got a side job.

Id try filing the gap so u can screw it down more.

I don't think a small screw into it would be bad either. It looks like most of the force is not laterally so it shouldn't take much to hold it in place

Chariotoflove

> notsomethingstructural

Chariotoflove

> notsomethingstructural

10/05/2020 at 22:59 |

|

The splines arenít actually engaging anything I donít think, but yeah, the gasket is worth it.

Chariotoflove

> Poor_Sh

Chariotoflove

> Poor_Sh

10/05/2020 at 23:01 |

|

I was wondering about rubber. Iíve used it for shims before. If you recommend it here, I feel better about it.

Chariotoflove

> SilentButNotReallyDeadly...killed by G/O Media

Chariotoflove

> SilentButNotReallyDeadly...killed by G/O Media

10/05/2020 at 23:04 |

|

Good solutions. I think Iíll try the shim and move up the list from there.

Chariotoflove

> Jb boin

Chariotoflove

> Jb boin

10/05/2020 at 23:05 |

|

Ah yes, that looks more heavy duty for the job.

notsomethingstructural

> Chariotoflove

notsomethingstructural

> Chariotoflove

10/05/2020 at 23:05 |

|

I think some of why theyíre not gripping is the collar bottomed out. Thereís not much there but if you can get them to engage by hand at all then the packing gasket could push it into position where it really tries to hold it there.

I would also† clean out all the mating surfaces with a tooth brush and like throttle body cleaner or something.

Chariotoflove

> PowderHound

Chariotoflove

> PowderHound

10/05/2020 at 23:06 |

|

Yes, but since I donít think the grooves are fitting into anything like threads would, I donít think it would do much. I need more diameter added to the inside, I think.†

Chariotoflove

> OPPOsaurus WRX

Chariotoflove

> OPPOsaurus WRX

10/05/2020 at 23:07 |

|

Agreed. Either increase the friction or just anchor it with a bolt. Itís not the main force direction.

Poor_Sh

> Chariotoflove

Poor_Sh

> Chariotoflove

10/05/2020 at 23:08 |

|

Yup! It resists sliding, and the low durometer will squeeze into the crevices like the splines and slots. For this application I wouldn't worry about any of the standard failure methods (fatigue, thermal).

gmporschenut also a fan of hondas

> Chariotoflove

gmporschenut also a fan of hondas

> Chariotoflove

10/05/2020 at 23:09 |

|

One option could be to put something inside of that hole on the inner spline piece. May allow the clamp on the outer piece to really squeeze on it, without the inner spline piece flexing inwards .

also since the part is already screwed up as others have said , drill, tap and insert a screw. I donít think it will take a huge screw. Might be able to go with a 2-56, though 4-40 is probably more available

That slot for the alignment pin weakens the max clamping force.

Chariotoflove

> notsomethingstructural

Chariotoflove

> notsomethingstructural

10/05/2020 at 23:10 |

|

That was my original assessment too. Thatís why I added the end-on pic, so you could see that. Iíll try either the gasket or the aluminum shim first (flip a coin) and move up to the drill and bolt if I need to. The spindle has not only grime but rust in there, and needs a good clean for sure. A toothbrush is just the thing.

TheRealBicycleBuck

> Chariotoflove

TheRealBicycleBuck

> Chariotoflove

10/05/2020 at 23:11 |

|

I used the beer can shim trick on a set of handlebars and still have one on the seat post in my old Schwinn. It worked well in both situations - one splined, one smooth.

If the shim doesnít work, you might get lucky with a small U-bolt clamp or maybe a two-both pipe clamp.†

Chariotoflove

> Poor_Sh

Chariotoflove

> Poor_Sh

10/05/2020 at 23:11 |

|

Okay, I actually have some slips of rubber I used before to mount a water bottle cage band. That w ill be first thing to try then.

notsomethingstructural

> Chariotoflove

notsomethingstructural

> Chariotoflove

10/05/2020 at 23:13 |

|

I would go with the rubber first because itís less likely to damage the splines further than they already are. The aluminum probably wonít either but with the† rubber no chance.

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/05/2020 at 23:14 |

|

It's been great for a few things, like being a sandable filler, for example, but it's nothing to depend upon for any kind of lasting repair. IMO...

Chariotoflove

> gmporschenut also a fan of hondas

Chariotoflove

> gmporschenut also a fan of hondas

10/05/2020 at 23:14 |

|

One more vote for† the pin, then. Iíll definitely do that as my final solution. Iím a little wary of putting something in the groove, as if it doesnít work, Iíd have to get it out. I donít want to mess up the alignment pin seating properly.

Chariotoflove

> TheRealBicycleBuck

Chariotoflove

> TheRealBicycleBuck

10/05/2020 at 23:16 |

|

That gives me confidence then. Also, rubber gasket material was recommended, which I have handy. I like the two bolt clamp idea.†

Chariotoflove

> notsomethingstructural

Chariotoflove

> notsomethingstructural

10/05/2020 at 23:16 |

|

Agreed. Start low and escalate as needed.

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

10/05/2020 at 23:17 |

|

Thatís cool. Iím getting a lot of other good ideas to try anyway.

gmporschenut also a fan of hondas

> Chariotoflove

gmporschenut also a fan of hondas

> Chariotoflove

10/05/2020 at 23:23 |

|

I wasnít thinking the groove, I was thinking the ID of the inner splined bit keeping the slot free for the pin .

There might be a reason they did it that way , but it looks odd to have the pin on that side of the clamp and require the slot to be so long, allowing for greater flex.

nafsucof

> Chariotoflove

nafsucof

> Chariotoflove

10/05/2020 at 23:24 |

|

is this contacting and not allowing you to tighten it enough? maybe cut out that groove more to allow tighter clamping?

Goggles Pizzano

> Chariotoflove

Goggles Pizzano

> Chariotoflove

10/05/2020 at 23:25 |

|

I second the aluminum can. Itís what we used on bike handle bars. It might hold.

nafsucof

> Chariotoflove

nafsucof

> Chariotoflove

10/05/2020 at 23:26 |

|

you just donít want to add any rubber there. †this is an area you donít want any deflection. †best solution is to increase the clamping strength.

Shoop

> Chariotoflove

Shoop

> Chariotoflove

10/05/2020 at 23:42 |

|

Manufacturing engineer: drill a hole through and put a bolt through and get it running.†

Nom De Plume

> farscythe - makin da cawfee!

Nom De Plume

> farscythe - makin da cawfee!

10/05/2020 at 23:50 |

|

I voted for the temporary permanent fix as well. Something youíd need a torch to break the chemical bond.

What I really wanted to know is how many ugga duggaís he put outs at peak. Snapping metal under high load is not usually good for the soft fleshy bits or highly stressed joints and muscle fibers.

You can tell a Finn but you can't tell him much

> Chariotoflove

You can tell a Finn but you can't tell him much

> Chariotoflove

10/06/2020 at 00:04 |

|

Retaining compound might be enough to keep things together. We use it on occasion at work, but I have no idea how difficult it is to take things apart if you need to.

Loctiteģ Retaining Compounds, for Oily Loose-Fit Parts, Loctiteģ 680, 0.02 oz.

https://www.mcmaster.com/91458A121

4kc

> Chariotoflove

4kc

> Chariotoflove

10/06/2020 at 00:12 |

|

Cut up soda cans work well for this type of thing. I currently have a piece as a shim o n my bicycle handlebars and itís a dumb fixed gear without brakes and †has no problem holding up to me leveraging all my strength into the bars to slow down.

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/06/2020 at 00:14 |

|

†

Chariotoflove

> gmporschenut also a fan of hondas

Chariotoflove

> gmporschenut also a fan of hondas

10/06/2020 at 00:15 |

|

Ah okay. The slot is there for the pin to slide into and set at the end. Itís there to resist the force of pedaling, which is orthogonal to the slipping Iím taking about here. The previous generation that this replaces had no pin and relied on friction. It was prone to rotational† slipping from pedaling.

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

Rusty Vandura - www.tinyurl.com/keepoppo

> Chariotoflove

10/06/2020 at 00:15 |

|

I would definitely be looking at putting a bolt through that thing. Quarter inch, grade 8. Typically gold in color at the hardware store. The nut does not need to be grade eight. But Iíd get one with a nylon insert. I would say the spline situation is hopeless. And splurge on a cobalt drill bit of the same size.

Chariotoflove

> nafsucof

Chariotoflove

> nafsucof

10/06/2020 at 00:17 |

|

No, it actually doesnít meet there. But it does deform when you tighten the screw, telling me that itís maxed out. The holes start to misalign. I tried to show that in the head on pic.†

Chariotoflove

> Shoop

Chariotoflove

> Shoop

10/06/2020 at 00:19 |

|

That is a recurring suggestion, and I like it for the nuclear option. It will save me from needing to get a new crank set.†

Chariotoflove

> nafsucof

Chariotoflove

> nafsucof

10/06/2020 at 00:22 |

|

Interesting. Others thought rubber would be good. I can increase clamping strength with an outside fitting clamp, but I think I should still increase the inside diameter so as to not force the outside tube to warp too much.†

Chariotoflove

> Goggles Pizzano

Chariotoflove

> Goggles Pizzano

10/06/2020 at 00:23 |

|

That is a popular suggestion and a cheap one that should be reversible if itís not enough.†

Chariotoflove

> You can tell a Finn but you can't tell him much

Chariotoflove

> You can tell a Finn but you can't tell him much

10/06/2020 at 00:25 |

|

I tried loctite red. It seemed to hold for a while, but it wasnít space †filling.

Chariotoflove

> 4kc

Chariotoflove

> 4kc

10/06/2020 at 00:27 |

|

Yeah, that seems to be popular. Thanks for your experience. It gives me confidence.†

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

Chariotoflove

> Rusty Vandura - www.tinyurl.com/keepoppo

10/06/2020 at 00:30 |

|

Iím strongly considering it, although I think quarter inch may be too big. And I will need to get bits for this.†

PowderHound

> Chariotoflove

PowderHound

> Chariotoflove

10/06/2020 at 00:32 |

|

Ah so you basically need jb weld or a grinder

A Boy and His Longtail

> Chariotoflove

A Boy and His Longtail

> Chariotoflove

10/06/2020 at 00:38 |

|

Time to whip out ole reliable

All joking aside, the best long term solution is definitely replacement, but I think Iím on team bolt through the thing for the short term.

Chariotoflove

> PowderHound

Chariotoflove

> PowderHound

10/06/2020 at 00:43 |

|

Highlander suggested it but Rusty said it wouldnít hold long.†